Level Boarding - How Bad Is It?

By Ela

Posted: 20th February 2025. Last updated: 21st February 2025 (list changes)

This is part two of a small series I am writing about the state of the railways in the United Kingdom. The list below will be updated as time goes on and new parts get published. You can stay up to date with my research and progress by following me on Mastodon (historians.social).

- Level Boarding - The What, Why and How.

- Level Boarding - How Bad Is It? (You are here).

Abstract

We now know what Level Boarding is and why it's important. Let's now go out into the world and work out just how bad the situation is, as well as investigate why railway accessability is in such a mess.

In my first article on the topic of Level Boarding, I outlined the concept as it stands, both in the ideal sense and in the regulatory sense. We discovered that, despite there being a standard for platform heights, most rolling stock on UK rails was not built to that standard, creating trains that are inaccessible and sometimes, when conditions are right, dangerous for all but the most able bodied of passengers. In this article I am going to attempt to quantify just how bad the issue is by taking a look at several London terminal stations and measuring the Platform Train Interface (PTI) myself. Along the way, we will also question the legal framework around rail vehicle access and why Network Rail's infrastructure and RDG Rail Delivery Group. Originally known as the Association of Train Operating Companies (ATOC). member's trains are exempt from possibly the most comprehensive rail access legislation in Westminster's history.

So how does one measure a train?

Figure 1. Measuring the PTI as per GIRT7020.

Figure 1. Measuring the PTI as per GIRT7020.

There are two different measurements that we need to discuss. Firstly, there is the measurement of the platform (and train floor height) above the rail head. This is the GIRT7020 standard discussed in the last article. This was not measured for multiple reasons. Firstly, the measuring team (my friend Amir and I) would need to have track access, something that we are not getting any time soon. Secondly, these measurements have already been done for me. One quick Freedom of Information request to Network Rail later and I have a huge CSV file of every platform measurement in the country.

Figure 2. Measuring the PTI as per the Rail Vehicle Accessability Regulations standard.

Figure 2. Measuring the PTI as per the Rail Vehicle Accessability Regulations standard.

Instead, Amir and I set out to measure the relative distance between the platform edge and the train floor. We took two major measurements: the vertical (𝑦) and horizontal (𝑥) offset from the platform edge to the floor and (if different) any tread plate or other stepping device. This was achieved with a regular tape measure, placed at the midpoint (if not on a straight platform edge) and a photograph taken on an iPhone 13 (with the default camera). These measurements are also the ones as specified under the Rail Vehicle Accessibility Regulations. Here is an example of photographs of a Class 455 at Waterloo Station.

Figure 3. Measuring a Class 455 at London Waterloo with our tape measure, as if we were inspecting for RVAR compliance.

Figure 3. Measuring a Class 455 at London Waterloo with our tape measure, as if we were inspecting for RVAR compliance.

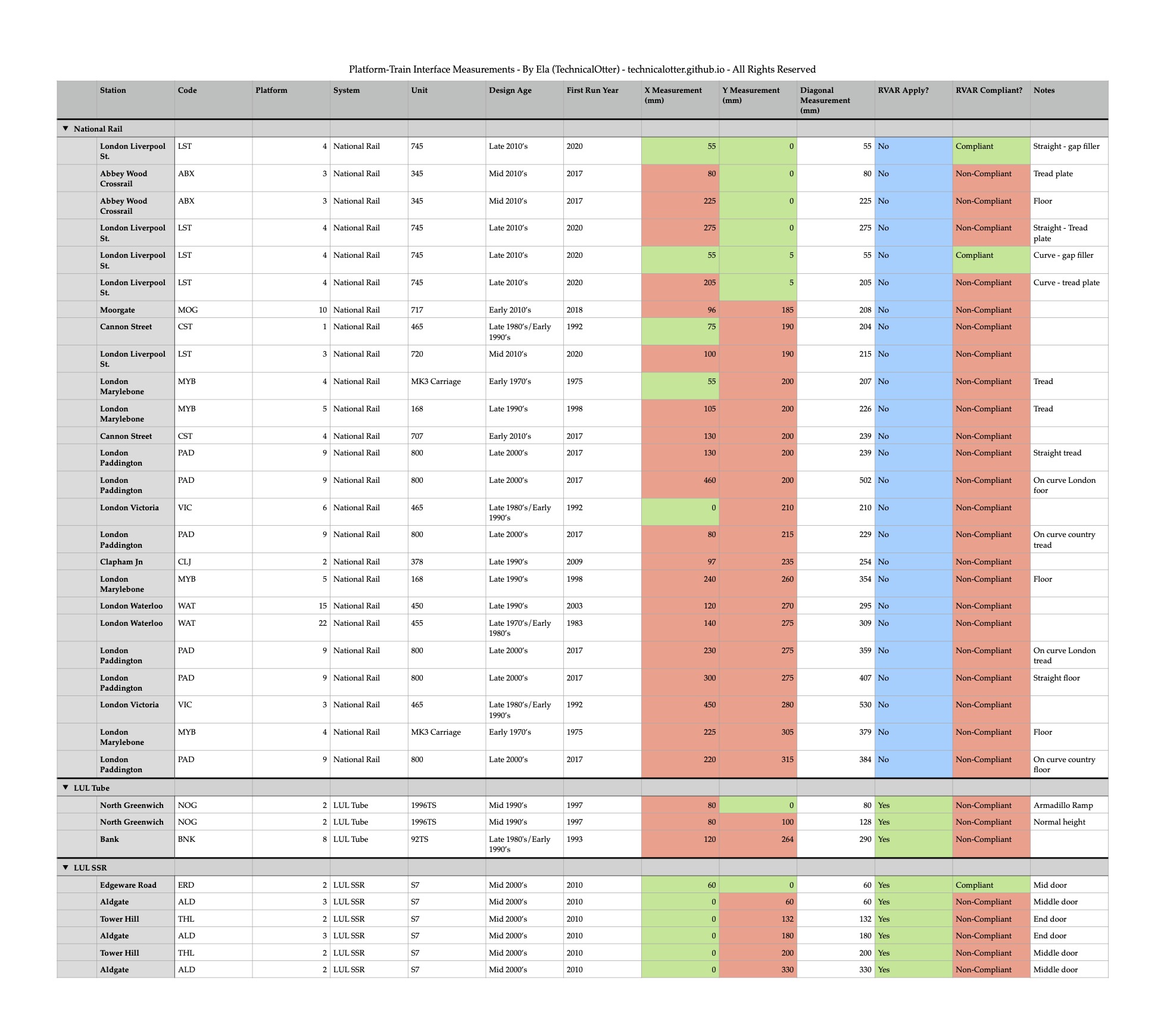

Our data was then compiled into a spreadsheet, allowing for this final table to be created:

Table 1. The big table of measurements from London. © Ela "TechnicalOtter - All Rights Reserved.

This table paints a very poor image of level access in 2024. However, before we dig any further, we must ask another question about regulations.

Rail Vehicle Accessibility Regulations - Good Intentions, Failed Outcomes

The Rail Vehicle Accessibility (Non-Interoperable Rail System) Regulations 2010 (RVAR) regulations are a very well intentioned set of regulations that sadly fail to help those who need them most. By far the biggest problem with them is the very limited application the regulations have. As the title suggests, RVAR applies only to "Non-Interoperable" systems - that is railways that are not part of the wider National Rail (and by extension, Trans-European Railway) network. As a result, RVAR does not apply to the 2,578 Estimates of Station Usage stations and 15,220 Rail Infrastructure and Assets registered passenger vehicles on the Mainline (National Rail) network. That is the majority of passenger rail vehicles in Great Britain Northern Irish railways are excluded as their railways are somewhat separate from those on the island of Great Britain. . While it is very noble to have regulated the non-interoperable systems and these regulations are producing good results where they are applicable, the fact they do not apply to the mainline railway allows Train Operating Companies to buy trains that are less accessible than they could otherwise be. RVAR regulations could be made to apply to the mainline and could force change. As RVAR's requirements are very good, requiring a very limited gap (𝑥: 75mm, 𝑦: 50mm), they will be used as the gold standard for rolling stock and platforms to meet. RVAR is possible to meet on the mainline (at least two items measured either meet or come close to the requirements in some form) and this proves that there is no reason why it should not apply.

So how bad is Level Access?

In short? Quite bad. However there is hope for the future. We will look at the data by breaking it down in several ways, namely by the system measured and the "class" Class in this case refers to the role of the vehicle e.g. intercity, commuter, metro, etc.of the rolling stock design. In other words, London Underground will be treated as two separate railways (the deep level tube and the sub-surface railway) and rolling stock will be considered based on if RVAR would or would not apply to it.

The results are disappointing at best, indefensible at worst. A total of 34 measurements were taken, across fourteen different classes of train. Of these only two trains were compliant with RVAR. Filtering for trains that were first used after 1998 (as vehicles made before this time are semi-exempt) we are left with five classes, of which only two (40%) are compliant with RVAR. In summary, the situation is bad.

There are some interesting trends within the data. Both the best and worst performers are from the Intercity category, while the suburban category has middling performance. Most interestingly, TfL's fleet suffers quite badly, however this is as related to infrastructure as it is to the design of the trains themselves.

The Mainline Situation

The Mainline situation is not a positive one. Twelve different models of rolling stock were measured in various ways and only one In other words, 8% of measured trains met RVAR requirements (albeit in a very creative, but sensible way). Surprisingly, the worst offender was not the oldest unit, but was instead a tie between two "intercity" class vehicles - the Class 800 (first ran in 2017) and the Mark 3 Coach (first ran in 1975). Despite having forty two years between them, the MK3 coach was *slightly* more accessible, depending on where exactly we measured from.

Intercity - New vs. Old

The Class 800 fleet was supposed to be the next generation of intercity unit for the UK's railways. These units began to be introduced from October 2017 on the Great Western Mainline. To quote then Minister for Transport Chris Grayling, "These new state-of-the-art trains show our commitment to put passengers at the heart of everything that we do and will carry people across Britain, from Swansea to Aberdeen and London to Inverness." All aboard the new Intercity Express trains that will transform journeys across Britain There is no denying that these trains have many state-of-the-art features. They're ETCS^[MarginNote European train Control System] equipped allowing for improved safety and potentially semi-automatic operation and are vastly more crashworthy than the Intercity 125 sets they replaced. However, easy access was **not** a priority when designing and building these trains. Firstly, the Class 800s and their siblings Classes 801, 802, 803, 805, 807 and 810 are compliant with the PRM2020 specifications. They do not comply with RVAR.

Their predecessors were a mixed fleet of Class 91 locomotives with Mark Four coaches (the InterCity 225 sets) and Class 43 locomotives paired with the Mark Three coaches. The MK4 fleet was not measured during this research for time related reasons. The MK3 coach was also available as a standalone locomotive hauled train and was the MK3 type measured. The MK3/Class 43 sets operated as semi-fixed High Speed Train sets. The MK3 was introduced in the mid 1970's to be 125mph capable coaches for the upgraded lines out of Paddington, Euston and King's Cross and to help British Rail compete with strong competition from airlines (remember, airport security was much less of a time penalty than it is now, making internal flights much more justifiable on a time basis). They were state of the art for their time and came from a time before GIRT7020 was the twinkle in an engineers eye, although most platforms in the UK were vaguely around the 915mm height. Britain has always had unusually high platforms compared with their European counterparts.

When we measured the Mark 3 coach, we found the tread plate to be 200mm above the platform height (𝑦 measurement), while being 55mm from the edge of the platform (𝑥 measurement). Not great but at least it's within RVAR's requirements for the 𝑥 measurement. This was measured at Marylebone Platform 4, where the average 𝑦 offset was 941mm (26mm from the standard) and the average 𝑥 offset was 710mm (20mm from the standard) and would be "within" RVAR's standards had the plate been at the correct height of 915mm. Unfortunately, even if the plate had been within RVAR's requirements, it still is not a level entrance as the floor is another 105mm above the tread plate and a full 170mm further into the coach.

Let's now look at the Class 800 and compare it to the MK3 coach.

| 𝑥 in mm | 𝑦 in mm | ||

| Class 800 | To tread plate | 130 | 200 |

| To floor | 300 | 275 | |

| MK3 Coach | To tread plate | 55 | 200 |

| To floor | 225 | 305 |

Despite the Class 800 being designed and built nearly forty years after the MK3 coach, the Class 800 has been a step backwards entryway accessibility. The gap between the platform and first point of contact on the train has increased quite significantly as a result of the narrower profile of the Class 800 fleet (1.7 metres vs 1.82 metres Class 802 and HST Trailers.). It is important to note, however, that the Class 800 has better accessibility overall, when compared to the MK3 (as originally built). The Class 800 does have power operated doors, more accessible bathrooms and better call for aid systems, not to mention the vastly superior crashworthiness of the vehicles.

Why is the Class 800 narrower? In one word, compromise. The cars that comprise the Class 800, as with all of the Hitachi AT300 family^[MarginNote This excludes the unique Class 395's operating on the High Spee 1 route] are three metres longer than the MK3's they replaced requiring a narrower profile to remain within the loading gauge limits on corners. This length increase has allowed for a significant increase in seating (around an 18% increase Intercity Express Programme), due to less space being wasted throughout the train on vestibules and gangways. This has, however, made access much harder for those with luggage or with reduced mobility; doors are now more likely to have a larger gap due to this longer length creating a greater end swing out when standing on a curve.

Stadler's Success

Let us quickly discuss why train floors, especially those on high speed trains, are quite high. It mostly comes down to the diameter of the wheels. Especially on High Speed Trains, larger wheels have several advantages - they ride better on rough track (aided further with yaw dampeners and suspension), they have higher inertia, meaning that while they are slower to get up to speed, they are more efficient at high speed. Sadly though, this means they make lower floors difficult. There is currently only one manufacturer of 125mph capable rolling stock with low floors (in the UK market), albeit a theoretical family design maximum rather than a UK product maximum. Stadler's Class 745 and 755 trains (part of their FLIRT family) are 100mph capable The FLIRT family can be ordered with a 125mph top speed. intercity trains that have low floors and are accessible to all without help.

Measured at Liverpool Street Station platform 4 (𝑥 (straight) - 746 mm, 𝑥 (curve) - 795mm, 𝑦 - 911mm), the Class 745 in question measured within RVAR's specifications, no matter if we were on a curve or on a straight edge. However, this was measured to the gap filler, the small retractable platform that fills the small (but non-RVAR-compliant) gap between the train floor and the platform edge.

| 𝑥 in mm | 𝑦 in mm | ||

| Gap Filler | Straight Edge | 55 | 0 |

| Curved Edge | 55 | 5 | |

| No Gap Filler | Straight Edge | 275 | 0 |

| Curved Edge | 205 | 5 |

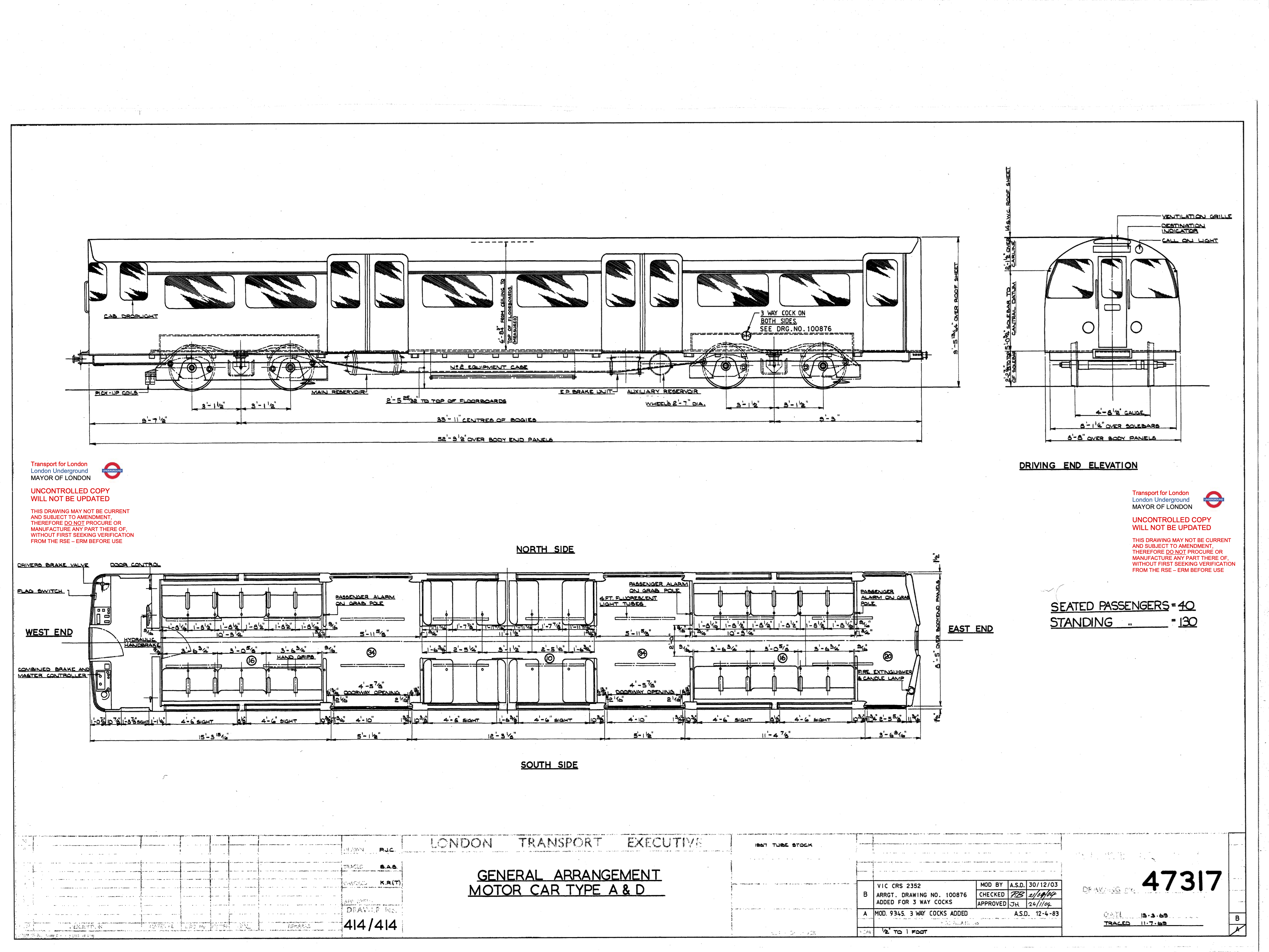

It is very clear that Stadler has done what no other UK market manufacturer is wiling to do - deliver a train that fits the platform and complies with a standard that should apply. Let's dig into how they achieved this. Firstly, Stadler moved the doors from the carriage ends to the centre of each carriage. This may seem like a tiny change but it allowed them to overcome the biggest problem facing high speed, low floor trains - the wheel diameter. As seen in the brochure for the Greater Anglia FLIRT's, the wheels are not much smaller than other UK wheels, especially the powered wheels who come in with a diameter of 870mm. UK Train Wheels generally fall between 760 and 1000mm in diameter The trick is that Stadler raised the floor height above the wheels. As this interior photograph shows, seats above the powered bogies are significantly higher, with a small ramp leading passengers up. This means that anyone who may either be wheeling or be traveling with wheeled luggage, push chairs, etc. can access the entire train with little difficulty.

Figure 4. Photograph of the inside of a Class 745, showing the raised floor over the powered bogie.

Figure 4. Photograph of the inside of a Class 745, showing the raised floor over the powered bogie.

Low floor rail vehicles that utilise a raised floor for bogies are nothing new and the technology has been used on tramways going back as far as 1984, when Geneva's public transport authority, Transports Publics Génévois (TPG), introduced the first tram with a Low Floor design. Harry Hondius, ‘The Development of Low‐floor Trams’ They are also not unique in Britain, even when discounting trams. Something often not realised by London Underground passengers is that for at nearly a hundred years, the wheels and bogies occupy space under the seats. If that seems a little odd, here's a drawing of a 1972 Tube Stock train (originally by the London Transport Executive!) showing what I mean.

Figure 5. Drawing of a 1972 Tube Stock, originally by the LTE, now property of TfL. Note how the wheels protrude up into the

vehicle's body, under the passenger seats. Obtained

via a Freedom of Information request.

Figure 5. Drawing of a 1972 Tube Stock, originally by the LTE, now property of TfL. Note how the wheels protrude up into the

vehicle's body, under the passenger seats. Obtained

via a Freedom of Information request.

Stadler took a similar approach here (albeit raising the whole floor, rather than just shoving the wheels under some bench seating), and as a result, floors on their FLIRT units are lower, making compliance with RVAR almost trivial. Moving the doors and lowering the floor would have already been enough to net them a goal here, however they went and ensured that goal was right in the back of the net, rather than just in by a hair. Rather than following the TfL solution of the "Bridging Device" that's deployed by staff, Stadler installed a gap filler on the train. This little platform does create a small (only a few millimetres) drop in the continuous floor height, but it fills the gap that would otherwise exist and creates a near seamless boarding experience for everyone, from the most able bodied to those who get around on wheels instead. Parents with push chairs, people with luggage, people with walking aids, really anyone benefits.

Figure 6. A photograph of a Class 745, showing the raised floor around the bogies from the exterior. © Greater Anglia

Media Centre.

Figure 6. A photograph of a Class 745, showing the raised floor around the bogies from the exterior. © Greater Anglia

Media Centre.

What's most upsetting is that Stadler have offered low-floor intercity trains that could have been the basis for the Intercity Express Programme (the overarching programme that bought in the original Class 800 and 801). Instead, we got Hitachi's design. An overall less accessible and poorly specified fleet that is objectively worse. Compared to the FLIRT200 (the 200kph/125mph capable FLIRT), the 225kph/140mph capable IET fleet is a joke for accessibility. We've already discussed it's failings under RVAR, I will also add that the IET fleet is unable to reach it's full potential of 225kph running because the signalling on the East Coast doesn't permit running faster than 201kph. With the (theoretical) building of HS2, I would argue there's little reason to go faster than 201kph on the mainline railway.

Suburban Services - Crossrail's Failure

As we've now ripped into the High Speed Fleet, let us now turn our attention to suburban rail. Suburban rail is worse than the intercity fleet, mostly because there are no level-access trains running at all. What's even worse is that there has arguably been a complete failure to the passenger in an attempt to provide accessible services. For most of the trains measured, the step up ranged from 185-280mm while the gap was anywhere from zero (mostly due to oversail, but even so, well done) to 450mm. Poor performance, but not a surprise. There is, however an outlier. While the gap is a little too wide for RVAR at 80mm, the Class 345 units on the Elizabeth Line core (the section between Paddington, Whitechapel and Abbey Wood) have no vertical step. How is this achieved? Sadly it's achieved in the objectively worst way possible.

Crossrail Core stations are not standard. They are built to a height of 1100mm above rail head to meet the floor height of the 345 "Aventra" units. RAIL Magazine, ‘Pidgeon Slams Crossrail for Non-Standard Platforms’ Rather than building a train that fits the (standardised) infrastructure, Crossrail chose to build infrastructure to fit the train. This has has dramatic consequences as a result. Firstly, it means that future replacement trains (when the time comes) will likely end up being non-standard, if other NR replacements are built with low floors. This means that the Crossrail fleet will be unique and specialised, rather than being standardised. One of British Rail's better ideas was having standard fleet building programmes, with trains being built around a standard bodyshell (e.g. a MK2, MK3 or Networker depending on the year) and as a result this lead to reduced development costs for new trains. Crossrail has undone any potential for that by ordering Aventras.

Secondly, this decision has (and continues to) injure railway users. At Ealing Broadway (not part of the core), there have been multiple people who have fallen down the gap between the train and the platform. Tom Edwards, ‘Minding the Gap at Ealing Broadway: “It’s a Death Trap”' This is on a railway that is touted as being "accessible" by it's builders and operators. It's a disgrace. People are being injured on what is being sold as a safe and reliable mode of travel. Furthermore, there's no easy fix. Massive infrastructure works would be required. The shared railway cannot have it's platforms raised because freight and non-TfL services operate through Ealing Broadway on the "relief" lines and the core cannot be raised as then it would be no longer accessible. The solution would require the core trackbed being raised, while also purchasing new trains that are actually in compliance with the wider railway regulations. This is not only expensive, but may also require the station tunnels to be re-dug in a way to allow the OLE and other supporting equipment to be moved, further increasing the time and cost required.

So who is responsible for this? After doing some digging, I was able to obtain the following letter sent from the Department for Transport to Crossrail, entitled "Crossrail Central Section: Dispensation against the notified National Technical Rule for Platform Heights". In it, the DfT authorise the higher 1100mm high platforms for the following reasons:

To achieve level boarding with a 915 mm platform height would mean the floor height in the new trains would have to be lower and this would severely compromise the design of the train creating a lower gauge profile as the train becomes wider.

A lower floor height would mean that more traction equipment would be required to be fitted above the floor level resulting in less available space for seating inside the train.

The trains would be more expensive because it would not be a standard design.

The wider gauge profile of a train with the 915 mm floor height creates a number of compatibility issues between the train and the older legacy platforms outside the central operating section, such as encroaching too near to these platforms to be within the allowed gauge profile.

Further digging turns up various documents from Crossrail, however there appears to be nothing after 2015, at least not online. This may warrent a trip to the National Archives someday. From what I've gathered, it would appear that Bombardier is responsible for this height, as the drawings of a "Crossrail Reference Vehicle" show a shape similar to that of a FLIRT, and as we've seen, they have Level Boarding.

Let's now analyse the statements in the DfT letter, one by one.

1 - A lower floor severely compromises the design of the train

This is false. Looking only at trains that were ordered before the Class 345 Crossrail order (February 2014), there are two design examples from Bombardier itself that could have been selected for Crossrail, that have low floors, without severe compromises to the train design. The first is from their "Movia" metro family - the S-Stock. We will talk about the S-Stock in detail later, but for this discussion, they have lower doorsills (at 980mm). Interestingly, an S-Stock is only 16mm out of spec when at a GIRT7020 platform, which it isn't designed to use. It's not the 915mm of GIRT7020, but another Movia train bought for London Underground (the 2009 Stock) has a floor height of 735mm. While those are notably compromised (due to there being restricted headroom as well), it is clear that a low floor trains can be built without too much compromise. Half of the trick with the S-Stock is having a small slope from the main floor height to the door.

Secondly, perhaps even more embarrassingly, the French have succeeded where the British failed. As part of a massive fleet renewal for a large number of commuter lines in and around Paris (including the RER), the Nouvelle Automotrice Transilien (NAT), nicknamed Francilian was purchased from Bombardier. These sleek but slightly hamster-faced trains show how it is done. According to Bombardier's own website, the floor height on these is 920mm. Bombardier, ‘SPACIUM Commuter Train - Ile-de-France' Even better, they are equipped with the magical gap fillers, bridging any gaps. Looking at photographs, as well as it's service record and reception, the design doesn't appear to be that compromised, apart from their 3+2 style seating (done to achieve similar seating levels to a full length 345 in about half the length). We should now ask the following: would this train fit the Crossrail loading gauge? The answer is maybe. As I've been unable to scrounge up anything before 2015, it's hard to know if Crossrail's tunnel designs have been modified specifically for the 345's. Sadly I don't have details about the Francilian's kinematic envelope, nor are the Crossrail Reference Vehicle's details available. Let's assume it's a maybe and that the design could have been slightly modified for Crossrail. They are 3060mm wide, while the 345's are just 2772mm, so some EMD-spec squishing The EMD Class 59/66 are effectively SD-40's squished for the UK. would need to occur, but if the SD-40 can be squished for the UK, I would bet the Francilian could be too. That and Stadler proved it possible, albeit four years after the 345 order went in.

2 - Lowering the floor reduces seating space as traction equipment must beplaced above floor height.

This is a point that is very valid. Stadler didn't work magic with the FLIRT's, with the transformers and a load of other equipment seemingly housed in a couple of gubbins cupboards in the middle of the train. It's not a huge amount of space, about 1/2 a car length over a whole train, but that is a significant amount of space that could otherwise be used for passengers.

On the flip side, Crossrail was built with large amounts of extra space for lengthening the trains in the future. It therefore is reasonable to argue that if they are able to engineer an extra four cars of space into all designs, half a car extra shouldn't be too much of an extra reach.

3 - The trains would be more expensive because it would not be a standard design.

Nothing about a UK train is "standard" when compared to international projects. Our trains have a notably smaller loading gauge and have weird safety systems found nowhere else. This order was always going to be expensive and unique, due to the myriad of special requirements for Crossrail operations. Lowering the floors would cost more, but I would argue it's within the projects scope. By buying high-floor trains, you've effectively kicked this problem into the future. When low floor becomes the standard (which it will, there's good reason to hope that the status quo of high-floor on GB rails will pass), you're now stuck procuring unqiue and expensive stock because your earlier trains weren't low floor.

4 - The wider gauge profile of a low floor train would interfere with the classic platforms

This is a joke of an excuse. The Stadler order required work to be done across the East Anglia network to be within the standards and allow for the new trains. This reeks of "we can't change what's already built", as well as a classic British fear of capital expenditure. When half of the issue is ensuring that the platforms outside the core meet the GIRT 7020 standard, this is a joke! Fixing the platforms so they meet the standard is something you should be doing anyway!

Furthermore, this would have been an excellent time for both Network Rail and Crossrail Ltd. to invest in some long term skills for the railway. Amir also points out that the complete failure for this point to be communicated through the relevant government agencies that could elicit change. A rolling programme of platform improvements (to meet the standard) across all Network Rail property could have been started with the lines that Crossrail would touch. This team could then continue on to work on all other non-compliant platforms across the network, slowly but surely bringing all into standard. Rolling programmes are how India electrified their entire network in record time; there's no reason why Crossrail couldn't have been the catalyst to re-evaluating the status quo and the start of something much larger and better for the network. Once again, a stupendous lack of vision and strategy on show from the British railway industry.

So who's to blame for such a poor end product? I place the blame with the DfT and HM Treasury. The DfT allowed for such violations of the standards to go ahead, while Treasury is concerned about capital costs and were willing to bend to Bombardier's unwillingness to provide a better vehicle. This is furthered by the political optics of awarding the Crossrail contract to a "British" Bombardier are a Canadian company, with British manufacturing capacity. manufacturer after allowing the Thameslink order to be built in Europe. It is clear to that there is very little interest in actually delivering quality products from the Government, railway operators and from Bombardier. Politics and this false idea that capital costs matter (they do, but it's a case of being smart about your spending) on large infrastructure projects. The Department for Transport and HM Treasury have locked themselves into a situation that will cause them to end up spending much more in the long term and into a situation that could theoretically open them up to legal liability. Note I am NOT suggesting there is any legal liability, I am speculating there could be if someone was so inclined. The future requirements to re-engineer the Crossrail core, combined with the current disgusting and dangerous situations being created over a majority of the network will cost the DfT, HM Treasury and the UK, both in capital (with re-engineering) and in lost productivity and potentially lost lives due to injury caused by the atrocious PTI at some Crossrail stations.

For fun, let's compare the Ealing Broadway vertical component - about 300mm Edwards - Minding the Gap - to the gap between a Class 455 and Waterloo platform 22. The 455 is a 1980's era MK3 based commuter EMU. It's nothing special, but they are a staple of commuter services in and out of Waterloo. They also come from a time where level access was effectively a non-consideration. The 455's measurement was also on a slight curve, as platform 22 has a slight curve to it; this puts Ealing Broadway at an advantage, being an arrow straight platform. The results? The 455 had a vertical gap of 275mm. From this we can conclude that we have made negative progress in the design of our rolling stock.

To call this shameful is an understatement. Our flagship commuter railway project fails to deliver basic access for all and is actively injuring people. It's non-standard to boot. This is a very dangerous precedent to set. As Gareth Dennis notes in his book, the railways are the major player in solving a lot of our current and future problems, from climate impact, to housing, to traffic. Gareth Dennis, HOW THE RAILWAYS WILL FIX THE FUTURE : Rediscovering the Essential Brilliance of the Iron Road (REPEATER, 2024) We cannot be building non-standard, non-compliant railways if we want them to be the critical tool they will are to meeting our current and future transportation requirements. I hope things will change for the better.

Where next?

We've covered a lot in this article. Hopefully it has given you a better idea of how bad the level boarding issue is. If you are interested in the data collected, I have included it as an image in the article. Please remember to reference the work, if you choose to do something with it!

The most important change needs to be that RVAR is to apply to all new rolling stock and structure constructions on the network. This includes alterations to existing platforms. Platforms should always be built to meet the GIRT7020 standard. Otherwise we can never have a system that is built for all.

The other big change is we need to see a shift in how we understand our railways and the costs associated with the equipment used. This is not just a question of capital costs, but lifecycle costs and more importantly the social and economic costs that surround the equipment. Inaccessible rolling stock only creates negative outcomes for the railways. We need the industry and the governments involved to understand this. Otherwise we lock ourselves as a society into a state where we are wasting time, money and energy on transportation, as well as making people dependent on others and preventing them from participating in society. It's disgusting we've let it go on this long. It's about time we changed it.

I'm not sure where I'll go next with this. I've got a load of notes on Ealing Broadway in particular, but also have a long list of research relating to the DfT-ification of our rolling stock. Let me know what you would like to see next! I can be found on Mastodon.

Notes

Unless otherwise stated, measurements of platforms relating to GIRT7020 are given as averages.

Acknowledgements

This piece would not have been possible without the help of Amir Dawoodbhai. Amir also followed me around London and helped with the measurement of the trains in the middle of summer.

Bibliography

- Bombardier. 2018. ‘SPACIUM Commuter Train - Ile-de-France - France - Bombardier’. 13 January 2018.

- ‘CD Of London Overground, London Underground, iBus Annoucements & Techincal Drawings Of Tube Trains & Latest LU/DLR/LO Fleet List - a Freedom of Information Request to Transport for London’. 2015. WhatDoTheyKnow. 1 August 2015.

- Dennis, Gareth. 2024. HOW THE RAILWAYS WILL FIX THE FUTURE : Rediscovering the Essential Brilliance of the Iron Road. [S.l.]: REPEATER.

- Edwards, Tom. 2024. ‘Minding the Gap at Ealing Broadway: “It’s a Death Trap”’. BBC News, 3 May 2024, sec. Transport.

- Hondius, Harry. 1993. ‘The Development of Low‐floor Trams’. Journal of Advanced Transportation 27 (1): 79–102.

- Hotchkiss, Jeremy and Department for Transport. 2018. ‘Crossrail Central Section: Dispensation against the Notified National Technical Rule for Platform Heights’, 11 May 2018.

- RAIL Magazine. 2018. ‘Pidgeon Slams Crossrail for Non-Standard Platforms’. RAIL, 3 August 2018.

Changes

Content changes are denoted in bold.

21st February 2025

- Update where data can be found.

20th February 2025

- Initial Post.

Mobile users may tap on instances of ‡ and citation numbers to view the sidenotes inline.